Facts About Aws Cwi Revealed

Facts About Aws Cwi Revealed

Blog Article

The Basic Principles Of Aws Cwi

Table of Contents5 Simple Techniques For Aws CwiThe smart Trick of Aws Cwi That Nobody is Talking AboutUnknown Facts About Aws CwiAbout Aws CwiAn Unbiased View of Aws Cwi

Third-party quality control evaluation of steel fabrication fixate welding evaluation, in addition to examination of bolting and painting of structural steel. KTA's steel inspectors offer Quality Control (QC) assessors to supplement fabricator's/ service provider's internal QC team and on jobs that mandate keeping the services of a certified assessor (e.g., CWI) utilized by an independent inspection firm.Examiners conduct visual inspections of product for uniformity with the accepted specifications, strategies and codes, as well as confirmation of Certified Product Test Reports (CMTR) for products made use of. Products and elements are observed at bottom lines along the production procedure in both steel mills and steel construction shops. KTA's licensed welding inspectors also witness welder and welding treatment qualification examinations as applicable to the scope of the project.

Steel fabrication evaluation solutions additionally consistently include carrying out non-destructive screening (NDT), also known as non-destructive exam (NDE), consisting of Magnetic Fragment Evaluating (MT), Ultrasonic Testing (UT) and Liquid Penetrant Evaluating (PT). KTA's evaluation solutions consist of coating inspections covering surface area prep work, paint, galvanizing, and metalizing.

KTA's ideology is to respond promptly to clients' needs, match the best assessor to the work, and provide the requisite documents. KTA has the support personnel to offer technical consulting to the area workers and to the customer. KTA has experts available to seek advice from on welding, NDT and finishings.

FST Technical Services is your worldwide companion in the Semiconductor and Drug Industries! Our placements include benefits such as medical, dental, vision, life, 401(k) with business match, PTO, paid vacations. Come sign up with an incredible group in an exciting, fast paced, and ever-growing sector! We are seeking a CWI's and/or NDT Level II certified Welding Inspectors from in and around the Lithia Springs, GA location! Town prospects are urged to apply yet this placement is open to travelers with mobilization and regular monthly per diem for those living outside the local location.

Some Ideas on Aws Cwi You Should Know

Semiconductor, Customer Products, Biography & Biopharmaceutical, and so on. Ideal candidate will certainly have high purity piping inspection experience. Current AWS certs are wanted. CWI's and NDT Degree II's very motivated to apply.

Pro QC's third-party welding assessment solutions consist of: Record Testimonial Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Testing (NDT) Others Our welding assessment records are delivered within 24-hour and record all inspection factors relevant to see high quality, consisting of all determined weld flaws and digital pictures (Welding Inspection Agency) (https://www.reverbnation.com/awscw1w3lding). Pro QC's group of examiners delivers third-party welding inspections around the world, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the UK, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the USA, Mexico, copyright, Brazil, Peru, and much more countries

Examination of the welding job is vital for proper quality When your business is taking care of significant projects with requirements for 3rd party independent welding evaluation, we offer excellent welding witness inspection services to confirm that welding has actually been executed according to many applied welding standards and specs. AQSS carries out welding evaluation solutions for clients from a selection of industries.

Things about Aws Cwi

Not complying with effectively certified welding procedures commonly leads to a weld of subpar quality, which can enhance the manufacture's possibility of failing under desired solution conditions. By examining for problems, our assessors can help customers guarantee that their welds satisfy relevant standards of quality control (AWS CWI). Weld evaluations are carried out for several factors, one of the most common of which is to identify whether the weld is of ideal quality for its intended application

Our welding inspectors have actually the needed qualifications with years of experience with evaluation and are acquainted with the majority of applied welding standards and specifications. AQSS has actually CWI licensed assessors.

The Basic Principles Of Aws Cwi

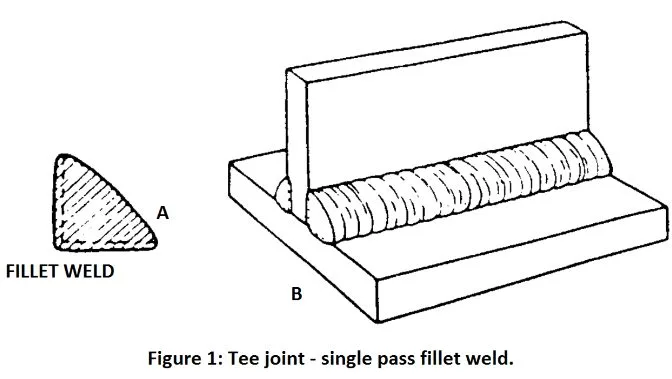

Typically, our assessors are inspecting for splits, pits, surface area pores, undercut, underfill, missed out on joints, and various other facets of the weld.

Samples can additionally be taken at periods throughout the manufacturing procedure or at the end of the run. Devastating screening samples are precisely reduced, machined, ground, and polished to a mirror-like finish. An acid etch is after that applied to visually draw out the weld, and the example is after that examined under a microscope.

Report this page